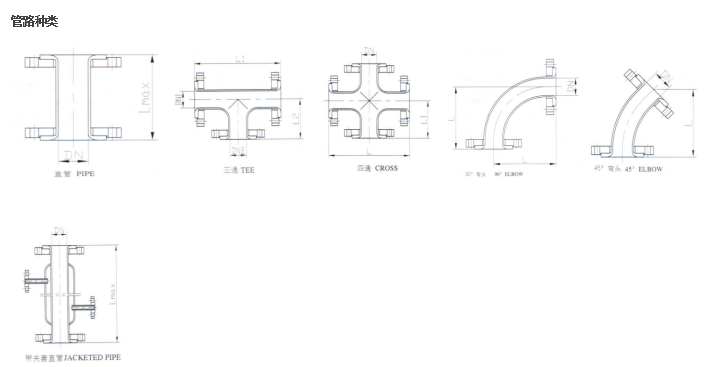

GLASS LINED PIPE

Low-carbon steel tubes (e.g.,Q235B), internal sandblasted to Sa2.5 cleanliness.

Fabrication Standards for Glass-Lined Steel Tubes

1. Base Material

Low-carbon steel tubes (e.g.,Q235B), internal sandblasted to Sa2.5 cleanliness.

2. Glass Formulation

Industrial glass enamel (SiO₂≥65%), CTE ≈3.3×10⁻⁶/K matching steel substrate.

3. Firing Process

Multi-coating & firing (850~930°C), layer thickness 0.8~2.0mm, zero bubbles/pinholes.

4. Quality Control

Compliance with HG/T 2370-2017, 20kV spark testing, thermal shock resistance ≥200°C.

✅ Corrosion Resistance: Withstands all inorganic acids (except HF) and organic solvents (pH 1~14).

✅ Non-stick Surface: Ra≤0.5μm roughness, preventing material adhesion.

✅ Thermal Stability: Operating range -20°C~200°C, thermal conductivity 0.9~1.2W/(m·K).

✅ Mechanical Strength: Compressive strength ≥200MPa, enamel Mohs hardness 6~7.

Chemical Processing: Acid/alkali transfer lines, reactor/condenser/evaporator connections

Pharmaceuticals: High-purity fluid transfer, sterile production systems

Environmental Protection: Scrubber towers, wastewater neutralization

Food Industry: Sauce/fermentation liquid transportation