60m3 RUBBER LINED REACTOR

设计标准:HG/T 20677-2013《橡胶衬里化工设备》 | GB/T 18241.1-2014

Design Standards: ASTM D380-14 | DIN 28053-2

Component | Material Options | Properties |

Base Shell | Q235-B Carbon Steel/304 SS | Blasted Sa2.5, anchor profile 50~100μm |

Lining Layer | Natural Rubber (NR)/Butyl Rubber (IIR) | Thickness 3~6mm, post-vulcanization 60~85 Shore A |

Adhesive Layer | CR cement + hard rubber interlayer | Peel strength ≥6 kN/m (ISO 8510-2) |

Lining Process

Hot Vulcanization: Steam 0.3~0.5MPa @140℃±5℃

Cold Vulcanization: Room temperature curing

Key Structures

Flange Seal: Rubber flange + steel retaining ring (PN0.6MPa)

Agitator: Rubber-clad shaft + 316L impeller (≤25m/s tip speed)

Heating: Jacketed steam (direct steam injection prohibited)

Connections

Manway DN450, Sight glass φ150mm (tempered glass + rubber gasket)

Advantage | Technical Highlights |

Abrasion Resistance | Elastic buffer withstands slurry (≤40% solids) |

Cost Efficiency | 1/8 cost of titanium-lined reactors, low maintenance |

Hybrid Lining | Zone-specific lining (e.g., EPDM for alkali + IIR for acid) |

Anti-fouling | Surface resistivity <10⁹Ω, prevents electrostatic adhesion |

Parameter | Standard Range | Limits |

Design Pressure | -0.1~0.4MPa | 0.6MPa (custom) |

Temperature | -20℃~+85℃ | +100℃ (EPDM, short term) |

Compatible Media | 50% H₂SO₄, 30% NaOH, brine | Prohibited: Ozone, strong oxidizers |

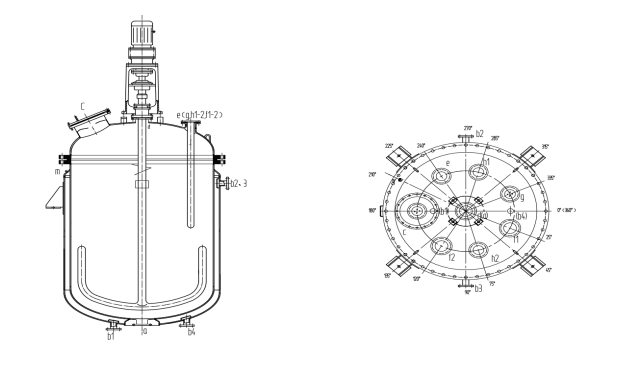

Nozzle 管口 | Connection standard 连接尺寸 | Application用途 |

a | / | Manhole 人孔 |

b | HG/T20592-2009 | Agitator hole 搅拌孔 |

c | HG/T20592-2009 | Temperature hole 温度计口 |

d | HG/T20592-2009 | Discharge hole 排净口 |

e | HG/T20592-2009 | Reserve hole 备用口 |

f | HG/T20592-2009 | Pressure gauge 压力表口 |

S1-2 | / | Sight glass hole 视镜口 |

H1-4 | HG/T20592-2009 | Jacket inlet and outlet hole 夹套进出口 |

K1-2 | HG/T20592-2009 | Reserve hole 备用口 |

m | Inner screw, G1/2” | Jacket vent hole 气体出口 |